1. Selection of Raw Materials

We only use genuine leather of natural origin, tanned in the traditional way, without artificial additives or aggressive chemicals.

The selection is made manually, evaluating texture, resistance and tone.

Only hides with the quality needed to last for decades go into production.

2. Creation and Production of Molds

Each model starts on paper or fine wood, hand-drawn by the craftsman.

The molds serve as a guide to ensure precise measurements and uniformity, respecting the anatomy of the product.

3. Cutting the Leather

The cut is made exclusively with handmade knives and sharp blades, carefully following the pattern.

The craftsman follows the direction of the leather fibers to avoid deformations and make the most of the raw material.

4. Assembly and Preparation

The cut pieces are aligned and marked manually to receive the stitching.

The points are perforated with awls or hand punches, without the use of machines.

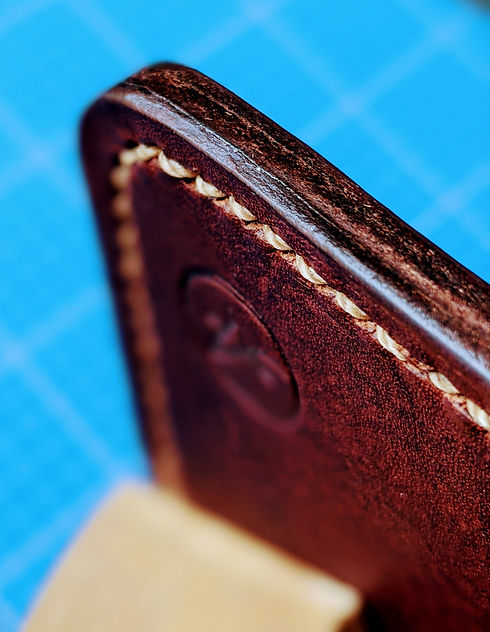

5. Hand Sewing

We use natural waxed thread and hand needles, applying the saddle stitch technique, which gives the seam superior strength.

Each stitch is reinforced to ensure durability and a flawless finish.

6. Finishing

The edges are polished with natural beeswax for protection and shine.

The leather is hydrated with natural oils, preserving its softness and strength.

Final inspection ensures that each part meets MANUFATURADOS's standard of excellence.

7. Packaging

We use sustainable packaging made from recycled paper and natural cords, avoiding plastics.

Each product comes with a leather care manual to ensure it lasts for generations.